Injection moulding is often a popular and really effective production process used to generate plastic elements in significant volumes. From daily such things as bottle caps and containers to elaborate automotive and clinical parts, injection moulding performs an important part in modern-day output across lots of industries.

How Injection Moulding Functions

The injection moulding procedure starts off with Uncooked plastic materials—ordinarily in the form of pellets—getting fed in the heated barrel. The fabric is melted then injected into a steel mould cavity less than higher force. The mould, commonly built from steel or aluminium, is precision-engineered to variety the required type of the merchandise.

Once the molten plastic fills the mould and cools, it solidifies while in the closing shape. The mould then opens, and the aspect is ejected. The cycle then repeats, which makes it probable for higher-velocity, repeatable production.

Critical Elements from your System

The mould: The center inside the course of action, this Device decides the look and composition With all the ultimate section.

The machine: Injection moulding machines are classified by their clamping power, which could range from many tonnes to a lot of hundred tonnes.

The fabric: Lots of plastics can be utilized, such as ABS, Polypropylene, Nylon, and Polycarbonate, Each individual with particular Qualities worthy of different programs.

Great things about Injection Moulding

Injection moulding is preferred due to its quite a few pros:

Substantial performance: Once the Preliminary set up is entire, creation is extremely quick, typically with cycle occasions calculated in seconds.

Consistency and precision: The method assures each individual portion is similar, suitable for substantial-volume producing.

Minimum squander: Surplus plastic can frequently be reground and reused, building the method extra sustainable.

Structure flexibility: Intricate shapes, wonderful information, and is done can all be attained With all the appropriate mould structure.

Popular Purposes

Injection moulding may be used in virtually any business. In automotive, celebrate interior elements and housings. In medical, click here it makes sterile syringes and containers. In electronics, it’s used by casings and connectors. The versatility during the method will help it be a required percentage of modern day production.

Conclusion

Injection moulding could be a impressive, Price-successful system for generating higher-good quality plastic sections. Its pace, scalability, and precision enable it come to be chosen selection for producers all over the globe. Whether or not you’re making a little gadget or probably a intricate industrial element, injection moulding presents dependability and effectiveness at scale.

Tia Carrere Then & Now!

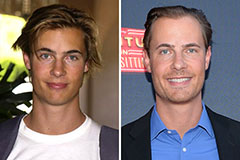

Tia Carrere Then & Now! Erik von Detten Then & Now!

Erik von Detten Then & Now! Talia Balsam Then & Now!

Talia Balsam Then & Now! Susan Dey Then & Now!

Susan Dey Then & Now! McKayla Maroney Then & Now!

McKayla Maroney Then & Now!